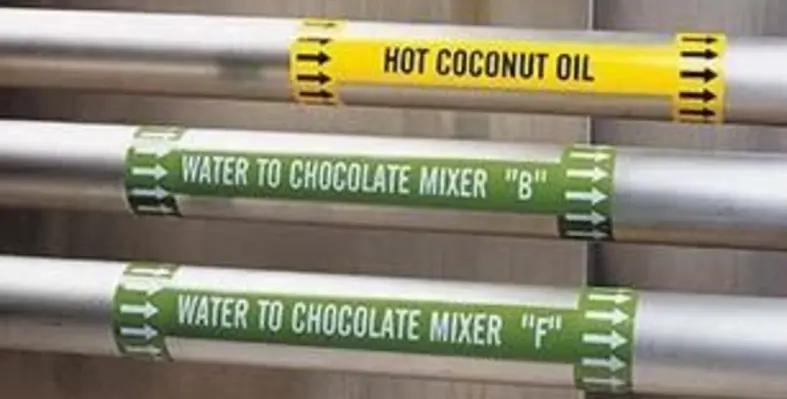

Pipe marking can quickly unveil any risks associated with a pipe’s hidden contents. (Image source: Brady Corporation)

Woodlands Dairy, one of the largest manufactures of UHT milk in South Africa, recently turned to Brady Corporation to provide a quality marking and identification solution that did not fade when exposed to heat, cold and liquids as well as being free of toxins to fully comply with food safety legislation