The Zest WEG Group is poised to commission the first total WEG control and automation solution sold to the African market at the Twangiza gold mine in the South Kivu province of the Democratic Republic of Congo (DRC)

The mine is owned by the Banro Corporation, a Canadian-based gold exploration and development company.

This fast track control and automation order was placed by Senet Projects towards the end of 2010 and incorporates another first for Zest, in that this is the first time that its innovative WEG SRW01 Smart Relays will be deployed on the African continent.

The order includes fully containerised MCC’s supplied by Shaw Controls, also part of the Zest WEG Group, as well as WEG Variable Speed Drives (VSD’s) and soft starters and an entire range of WEG LV switchgear. Significantly, all electric motors on this project were specified WEG.

Zest Group Business Development Manager, David Claassen, says his company is particularly excited about this order because it is the first fully integrated WEG automation and control solution supplied on the African continent.

“Senet Projects has shown an immense amount of faith in us, not only in terms of anticipated product performance, but also in regard to transporting all this equipment safely and on schedule to such an extremely remote site,” Claassen says. “The containerised MCC’s alone took eight weeks to reach the mine by road. Operating at 2 500 metres above sea level, all this equipment needed to be correctly engineered and sized to operate optimally in such extreme conditions

“We believe one of the key factors determining the placement of this order with us is our well established relationship with the client, our proven service and on time product delivery on various other projects.”

Most of the control and automation is already installed at Twangiza and is being commissioned by an on-site crew comprising both Zest and Shaw Controls technicians.

“Having a technical team from both Zest and Shaw Controls has allowed both companies to scale down their personnel requirements on this project and also narrows the risk to the client who is, in effect, dealing with one company,” Claassen comments.

WEG Variable Speed Drives

The WEG CFW-11 VSD with cutting edge technology for control of three phase induction motors was selected for the Twangiza installation. It can be used in a wide range of applications as it is designed for normal and heavy duty loads. The CFW11 carries various technology patents including vectrue technology (Quadratic V/F, sensorless and closed loop Vector control and VVW control) and optimal braking - (an alternative to the use of braking resistors for high inertia loads).

“The beauty of the CFW-11 is that it can be used in both simple and sophisticated applications, owing to its broad range of functions and easy configuration, installation and operation,” Claassen says. “The CFW-11 presents excellent static and dynamic performance, precise torque and speed control, dynamic response, positioning precision and high overload capacity.

Further development of the CFW-11 includes the addition of the Safety Stop innovation in accordance with EN 954–1, category 3 which disables the PWM pulses of the IGBT’s in an emergency stop condition as well as a Real Time clock which is used for accurate date and time log of fault diagnostics.

WEG soft starters have been designed to ensure the highest performance during starting and stopping induction motors. Starting methods include Voltage ramp, current ramp, current limit, pump control and torque control. Other features include a built-in bypass contactor which minimises heat losses and reduces panel size and cooling requirements, as well as various communication protocols (Profibus DP, DeviceNet, Modbus RTU).

WEG SRW01 Smart Relays

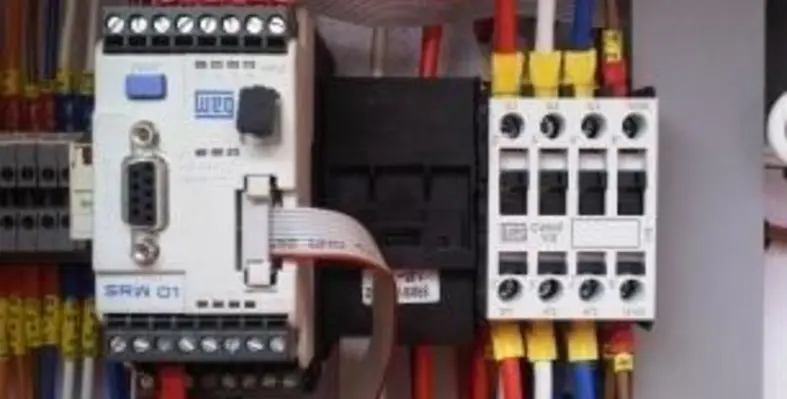

More than 200 innovative WEG SRW01 Smart Relays have been installed for the Twangiza Project, making this gold plant the first operation in Africa to install the reliable low voltage electric motor management system with state-of-the-art technology and network communication capabilities.

WEG SRW01 Smart Relays protect motors of high value and prevent extended downtime. What sets this technology apart in the marketplace is its ability to communicate with three different networks: ProfiBus DP, DeviceNet and ModBus-RTU. This advanced communication technology opens up a spectrum of previously impossible design options. Using plug-and-play technology, operators are able to change the communication protocol quickly and simply, while the system automatically recognises which protocol is in use.

Advantages of the SRW01 Smart Relay include enhanced reliability of the protection system and operator safety in operation, supervision and maintenance. This cutting edge technology also reduces the amount of control wiring and motor control hardware usually associated with relays.

Circuit breakers

Designed for the protection of high power electrical circuits, state-of-the-art ABW Air Circuit Breakers are part of the Twangiza installation. Features include a broad range of current adjustment and high short circuit interruption capacity. ABW air circuit breakers operate through a spring system, which can be manually charged through a front lever, or electrically through a motor. Remote operation is also possible via the closing and opening coils installed inside the circuit breaker. The closing coil is equipped with an “anti-pumping” electronic circuit, which prevents successive re-connections in a single command.

WEG ACW Moulded Case Circuit Breakers are also being installed at Twangiza. Standard features include voltage and frequency rating, interrupting rating, continuous current rating and accessories. Common plug-in accessories simplify field installation, while cascading protection offers an economical approach by facilitating the use of downstream, low-cost, low-fault level breakers to offer savings in both the cost and size of equipment.