Kal Tire’s Mining Tire Group, a dedicated tyre management and supply partner, details its Maple Program, a tool to quantify and reward saved oil and carbon emissions to help inspire a greener future

The Group has made clear its dedication to driving positive change across the globe, providing mining tyre expertise and innovations that help to drive fleet availability, sustainability and safety within operations. Earlier this year, the company spoke to African Review and shared more about how its growing footprint on the continent and the new solutions which are helping to support its future expansion trajectory. Following this, we reached out to Kal Tire again to learn more about its Maple Program, an initiative pioneered to support mining sector commitments to sustainability and best practice by accrediting efforts to extend tyre life with the company’s sustainable tyre solutions.

African Review: What is Kal Tire’s Maple Program?

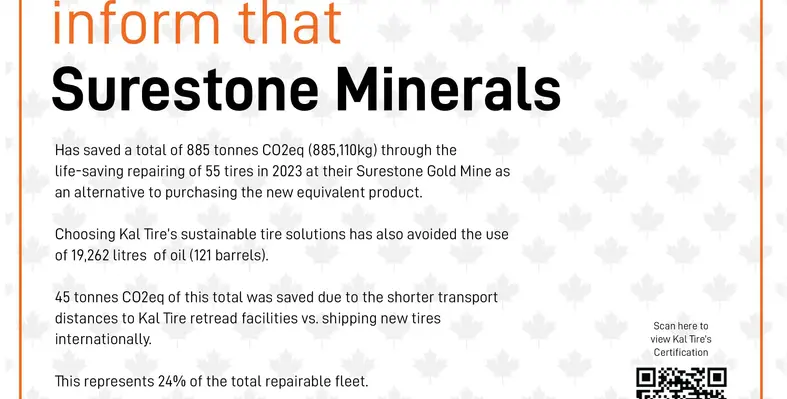

Kal Tire: The Maple Program provides Kal Tire's customers with validated data of the CO2 and oil savings made by choosing to retread or repair existing tyres rather than buy new.

New tyres require large amounts of raw materials in their construction and production energy is required in the manufacturing of these new tyres, particularly during the curing process. Additionally, CO2 is emitted transporting from manufacturer facilities to mine sites, which can often total many thousands of kilometres across sea, road and rail routes to get to site.

Kal Tire's Maple Program takes into account this reduction in raw materials, production energy and transportation distances to award customers with a certificate, rated with 1 to 5 maple leaves, depending on the percentage of the fleet, or total tonnage of tyres that have used these sustainable tyre solutions.

Up to 5 tonnes of rubber, steel, carbon black, oil and various textiles are used in a single 63" tyre used on 350 ton+ haul trucks. Each truck requires 6 of these tyres, and some larger sites can have many dozens of large haulers on-site. By choosing to retread or repair these tyres, customers can see potentially significant CO2 savings, sometimes totalling many hundreds of tonnes.

African Review: How powerful is a Maple certification today in an environment of ever-growing scrutiny around emissions?Kal Tire: As environmental scrutiny grows throughout the mining industry from governments, stakeholders and local communities, companies are increasingly investigating more ways to demonstrate their total emissions reduction. We have seen particular growth in companies reporting their retread and repair CO2 savings through the Maple Program over the last 12 months, who are displaying an increased appetite to report on their Scope 3 emissions, which applies to any activities from assets brought into operations from external sources, such as tyres.

We have seen some key African customers use the emissions data from the Maple Program in their ESG reporting to help reduce their Scope 3 emissions and mention the Maple Program specifically to help the drive towards more sustainable business practices.

We ensure the Maple Program is continually validated every year, which includes ensuring CO2 savings figures are as accurate as possible - for each region that Kal Tire operates in, local emission factors are used, which fluctuates annually depending on how energy is generated in the country - for example, coal-powered, nuclear, hydro energy, etc. Raw material figures such as the cost of producing rubber, steel and carbon black are also updated as part of this process, provided by the International Energy Agency (IEA). This ensures the program is always up to date and helps further motivate customers to protect their existing tyre investments.

African Review: Since the introduction of the Maple Program in 2019 how rapidly have appetites towards tracking environmental impact developed within the mining community, especially within the African continent?

Kal Tire: Several key customers across our operations in West Africa and southern Africa have embraced the value that environmental awards such as the Maple Program can bring. This has led to increased interest in our sustainable tyre solutions.

In West Africa, we launched a retreading technique called Ultra Tread. In this process, the tyre is removed after completing its planned hours on the front position of haul trucks. Instead of being rotated to the rear to run out the remainder of life, the Ultra Tread process is performed, restoring the tyre to its original tread depth and returning to the front position. As well as giving excellent return on investment and faster turnaround times than traditional retreading, it also carries great environmental value – up to 75% less emissions are used in the raw materials and production of these tyres vs. their new equivalent. Ultra Tread gives a whole new life to tyres on the front position and can be potentially performed multiple times.