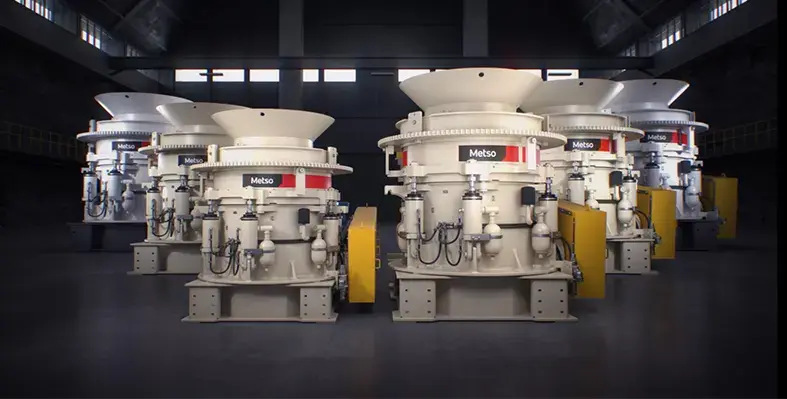

Metso has introduced three advanced cone crushers—HP600e, HP800e, and HP900e—expanding its latest generation of high-capacity crushing solutions

These models retain the trusted features of the existing range while increasing production capabilities for both aggregate processing and demanding mining applications.

“The evolution of Metso’s cone crusher technology brings multiple benefits and presents a true step change in terms of performance, uptime, serviceability, and application coverage. We are excited to expand the series and bring to market a wider offering of these high-performance crushers fit for different production purposes,” commented Ilkka Somero, product manager of HP cones at Metso’s aggregates business area.

“Efficiency is the key to meeting the industry's needs. With the robust new units, we can offer performance, longer lifetime, and higher cost efficiency to our customers,”remarked Nicolas Gallay, director of gyratory and large cone crushers at Metso.

The HP600e and HP900e models build upon proven designs, while the HP800e introduces a new option with a 600 kW / 800 hp capacity. Each unit includes two modern automation platform options: IC70C and MCP. These systems enhance visibility, monitoring, and control of the crushing process, while also enabling remote connectivity and digital services.

Enhanced crusher efficiency

The HP600e, HP800e, and HP900e offer:

Up to 15% greater capacity* and 35% higher crushing force* due to enhanced kinematics and increased power.

Optimised crushing chambers, reduced head spinning, and ring bounce detection to maximise efficiency and wear life.

A complete drive and sub-frame system for safer and faster installation while reducing dynamic load by up to 70%.

A new lifting tool for the feed cone, enhancing safety during wear part changes.

A core principle of this series is its upgradability. Operators with previous-generation crushers can integrate the latest features or upgrade components for improved efficiency and performance.

Metso offers various upgrade options for existing models, allowing seamless and cost-effective modernisation with the newest features. In addition to product enhancements, Metso provides installation, commissioning, inspections, refurbishment, shutdown support, lifecycle service agreements, and a full range of wear and spare parts.

All services and upgrades adhere to strict quality standards, ensuring optimal performance. Metso’s extensive distribution network further enhances customer support by delivering localised expertise, quick response times, and tailored service solutions.

With over 13,000 units in operation worldwide, these crushers remain a trusted choice for mining and aggregate industries.