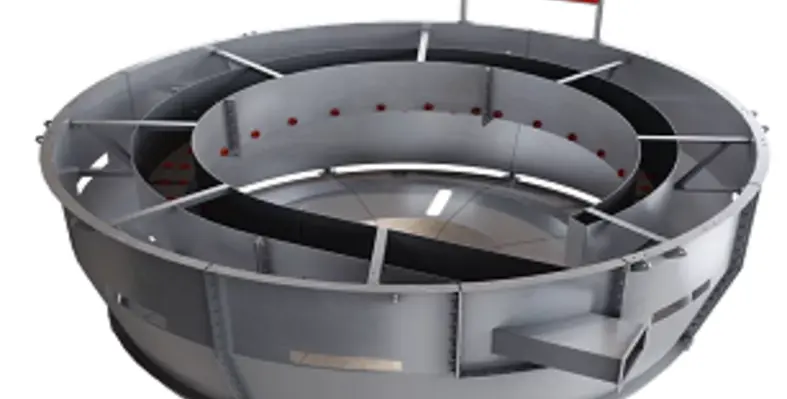

Finnish industrial machinery company, Metso recently launched the Reactorwell upgrade – a new generation feedwell upgrade – aimed at maximising thickener and clarifier performance while at the same time minimising flocculant consumption and bringing significant operational cost efficiencies

The Reactorwell upgrade – which is part of Metso's sustainable Plant Positive portfolio – enables a big leap forward in thickener and clarifier performance as it utilises maximum settling area due to its high exit symmetry. It also provides improved overflow clarity as well as higher underflow density. Additionally, the upgrade allows better thickener operability with an improved response to process changes.

Featuring high solids retention and mixing efficiency. the first-class feed system upgrade eliminates feed short-circuiting and offers low shear for ideal floccule growth and even discharge symmetry. Moreover, it also provides optimum feed conditioning for thickeners and clarifiers, with its design allowing it to be integrated into existing mining operations as an upgrade that is compatible with most makes of thickeners.

In addition, due to its intelligent design and modularity, the upgrade is easy to maintain and consistently achieves high unit area throughput. The improved Autodil performance also minimises the need for pumped dilution, leading to lower total cost of ownership.

“The Reactorwell’s design allows it to be integrated into existing mining operations as an upgrade that is compatible with most makes of thickeners," said Metso's senior product manager, Thickening, Andrew Mcintosh. "We offer expertise and support to retrofit existing infrastructure without major modifications. The Reactorwell can also be upgraded to a new channel configuration if process conditions significantly change.”

For more information, visit: https://www.metso.com/