The use of heavy working machines in mines and quarries and other demanding working conditions cannot be imagined without quality protection chains which offer tyre protection, improved grip and improved machine stability, according to Veriga

Quality is crucial when buying and using this product. That is why it is essential to have a reliable manufacturer; a partner with knowledge, years of experience and flexible production. These characteristics, and more, can be found in European company Veriga K.F.

The Veriga factory was established in 1922. The production programme included screws, forgings, heavy anchor chains, forestry towing chains, transport chains for mining, and various chains by metre, from thickness of 1 mm up to 100 mm.

Later, the production expanded onto snow chains and protection chains for tractors and heavy machinery, as well as snow chains for automobiles. Today, 100 years later, the company produces four different lines of products (forest, snow, tpc and sport), own a metal plating and heat treatment facility (as well as a testing laboratory), and is exporting to more than 60 countries all over the world.

Veriga TPC line

Veriga TPC is a range of tyre protection chains for heavy duty machinery used in mines, quarries and landfills, where tyre protection is the primary purpose of chains. They offer significant benefits including reduced tyre wear (three times reduction in tire wear costs per machine operating hour), better grip and machine stability even in the toughest conditions.

By using only the best materials and the most advanced processes, the chains are able to provide supreme protection and up to 50% longer tyre service life. Depending on the use case, various chain structures are available, providing the customer with an optimal choice and custom modifications to the product according to the complexity of the terrain and application.

In development and manufacture of protection chains, Veriga uses the best materials and heat treatment while drawing on the rich experience in the area of chains. Used material is suitable for heat treatment and contains the correct ratio of carbon and other alloying elements, which allow for high-quality heat treatment and thus a high degree of hardness, which ensures a long lifetime of the chain. The desired chain properties are ensured by the carburising process. Depending on the purpose of use, Veriga offers different types of chain and protection element constructions.

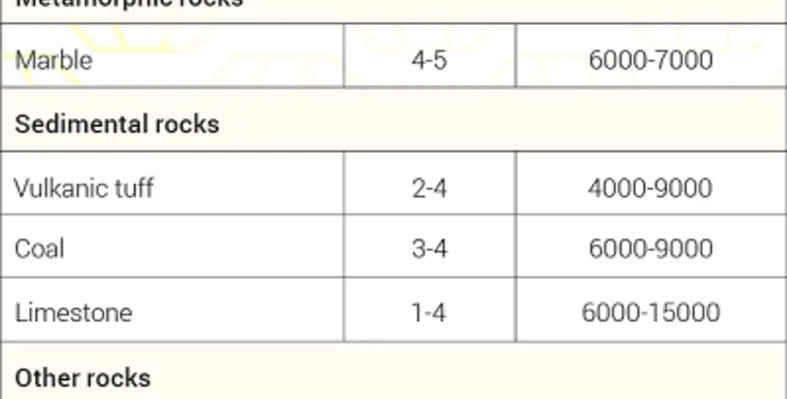

Depending on the conditions in which the protection chains are used, Veriga guarantees the following number of working hours:

Learn more about Veriga and Veriga TPC line on the website: www.veriga-lesce.com

Video: https://veriga-lesce.com/products/veriga-tpc/?lang=en

Catalogue: https://issuu.com/veriga.lesce/docs/veriga_tpc_katalog_en_es_web_1_