Safety on capital equipment at mines and quarries is fundamental, and while Volvo designs safety into every machine, there are additional tools customers can take advantage of to help ensure staff go home to their families safe and well at the end of every shift

1. Avoid dangerous overloading with On-Board Weighing

On-Board Weighing provides real-time payload information to the screen in the cab and uses external lights as a visual guide for the operator of the loading unit as to when the nominal load has been reached. The system is available for both articulated haulers and wheel loaders as part of Haul Assist and Load Assist respectively.

2. Prevent tire blowouts with Tire Pressure Monitoring System

The Tire Pressure Monitoring System in Haul Assist and Load Assist gives operators an instant and safe indication that tires are functioning within the correct parameters directly from the screen in the cab. Operators also receive visual alerts if there are inconsistencies in pressure or temperature, indicating that they should keep certain tires under observation and prepare to take action.

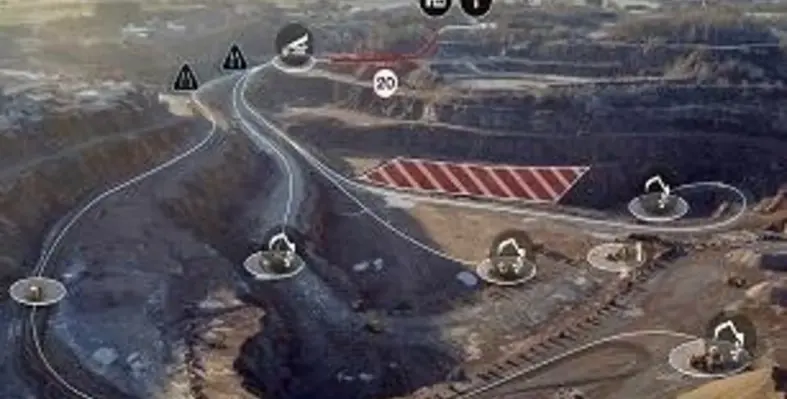

3. Limit speeding and improve awareness of other vehicles and staff on site with Map

The Map function in Haul Assist and Load Assist informs operators of the location of other machines and personnel on site, reducing congestion and improving safety. The function also issues speed limit notifications when necessary to remind operators to keep to the recommended speed for safer operation.

4. Identify safety training needs with CareTrack operator behaviour alerts

CareTrack telematics data can alert fleet managers to instances of unsafe operator behaviour and the need for training to improve skill and instil safe operating practices. Progress can be measured over time to assess the impact on site safety.

5. Ensure machines are always in safe condition and reduce movements of technicians on site with ActiveCare

With ActiveCare remote monitoring and proactive maintenance, an algorithm sorts through all the error codes and alarms transmitted via CareTrack to the cloud, prioritising cases according to urgency and severity, attributing probable causes. This helps plant managers to determine whether immediate intervention is required, enables engineers to remedy small issues before they can turn into dangerous problems, and always be ready with the right tools and parts.

To find out how Volvo can improve safety at mines or quarry, contact your local dealer today.