Traditional spray ball cleaning devices are static, and achieve most of their cleaning performance from cascading water on the tank walls, but rotary jet head cleaning from Alfa Laval may be a game changer in efficiency

It is argued that the traditional spray ball cleaning systems are static, meaning that the majority of the tank cleaning energy comes from water cascading down the tank wall at low wall shear stress. This form of cleaning requires a large amount of time, water and energy in order to compensate for poor tank cleaning performance.

Alfa Laval have introduced a unique jet head where its cleaning cycles hits the tank wall at an evenly dense cleaning pattern throughout the entire surface of the tank.

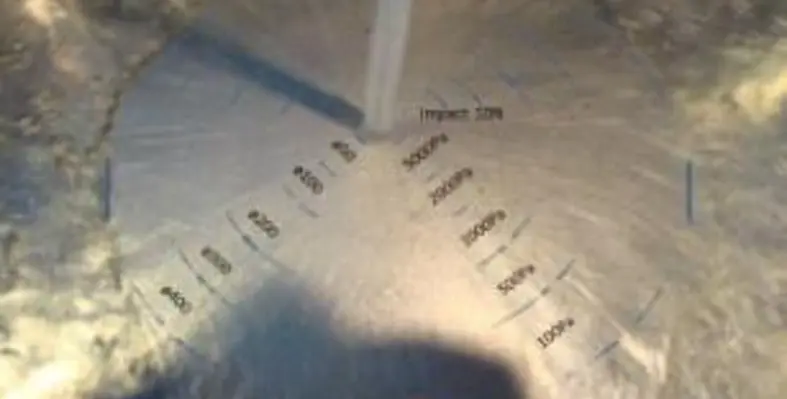

Alfa Laval explain the cleaning pattern as "When the water jet, coming from a rotary jet head cleaning device, hits the tank wall, it generates a force of impact (N). After impact, the jet spreads out and creates a cleaning footprint with high wall sheer stress force (Pa). As the cleaning machine is rotating in a 3D motion, the footprint is "moving" around inside the tank in a predefined pattern and cleans the entire tank surface with high wall shear stress. The further away from the impact point the less wall shear stress (mechanical action) is achieved."

Alfa Laval's Rotary Jet Head produces a wide distance between the footprint tracks. This means that if the product is easier to clean off, it only requires little wall shear stress to remove the product.

The cleaning cycle only takes between one and three minutes, while the Alfa Laval rotary Jet Head is a higher initial investment, the low operating costs offer a shorter payback time, which Alfa Laval say is recovered in less than a year.

The Rotary Jet Head can be viewed on Alfa Laval's website here.