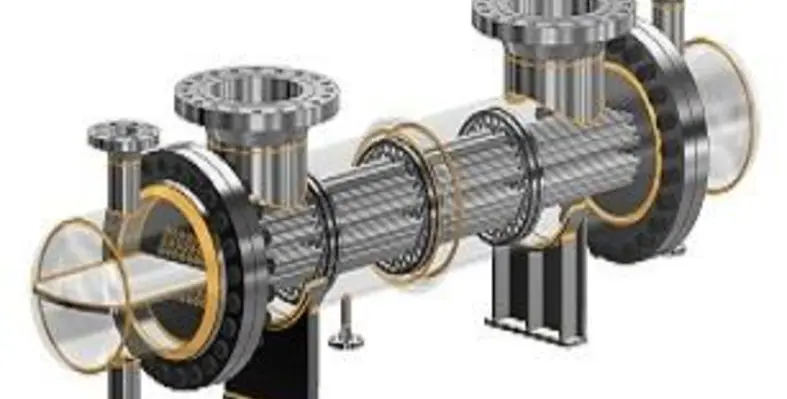

Steinmüller Africa, a South African company which brings local custom-engineered industrial shell and tube heat exchangers to sub-Saharan Africa’s process industries, has now introduced three-dimensional (3D) modelling to the heat exchanger and boiler design process to increase design accuracy while simultaneously reducing both turnaround times and costs for its clients

The new software replaces the traditional process of designing heat exchangers in logical steps, which sometimes results in part fit-up problems, impacting the design process and project execution. All heat exchangers from Steinmüller Africa are now designed purely as 3D models to begin with, which allows the various engineers to design and fit all required parts with minimal effort and to generate drawings along with the bill of materials, facilitating accurate pricing, even at the design stage.

Mohammed Khan, director at Steinmüller Africa, explained, “Our 3D modelling makes it relatively easy for our proposals department to obtain effective pricing, and our manufacturing department to accurately manufacture the heat exchanger with the least quantity of materials possible. This substantially simplifies the design process, allowing us to generate several different designs, time dependant, and identify the most cost-effective version while still at tendering phase.”

The 3D modelling is executed using parametric modelling in AutoCAD Inventor software and is uniquely linked to Steinmüller Africa’s intellectual property. This allows Steinmüller Africa to determine the best solution based on a client’s specific requirements.

Reduced manufacturing turnaround time is made possible because all teams – design, mechanical, procurement, and manufacturing – each have their input on the various design iterations before that phase is reached.

Khan added, “We offer a single customised, technically and commercially optimised solution to any client’s heat exchange challenges – and in a fast turnaround time.”

With this technology, Steinmuller Africa is now able to design and manufacture, complex heat exchangers for process plants that require a mixed phase flow.

“While the 3D technology used is not new in the industry, it has been predominantly used by overseas companies,” Khan surmised. “We have trained ourselves to do the design and manufacturing locally, positioning us ahead of competitors that commission offshore companies for heat exchanger design or manufacture – or both.

“We are now perfectly positioned to provide comprehensive solutions for boilers and heat exchangers across most industries, be they gas, fuel oil, coal, or unfired boilers that use waste heat, or heat exchangers within concentrating solar power plants.”