Volvo Penta will use its presence at CONEXPO-CON/AGG 2023 to highlight a commitment to sustainable power solutions to meet the industry’s net-zero ambitions

Volvo Penta will be presenting technologies and service offerings at CONEXPO-CON/AGG 2023 which will help support both the current demands to reduce emissions and the future business needs of construction and mining customers, as well as those operating in a range of other industrial applications.

As part of the Volvo Booth, F8926 in the festival grounds, Volvo Penta will showcase its electric driveline alongside its current portfolio of ultra-efficient Stage V and Tier 4 Final combustion engines – the D5, D8, D13 and D16.

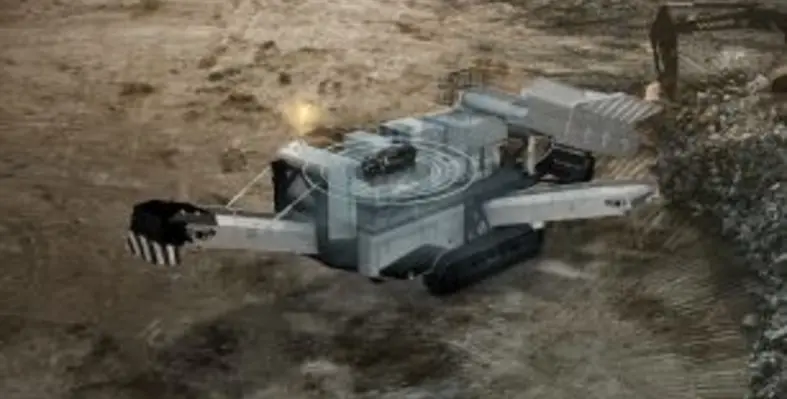

On top of all this, the company will unveil the expansion of a collaborative partnership with one of its customers. The North American OEM will showcase a new concept machine powered by Volvo Penta.

“We are looking forward to unveiling the expansion of our collaborative partnership with one of our OEM customers at CONEXPO,” commented Fredrik Högberg, president of Volvo Penta North America. “In order to succeed on our transformation journey into new, sustainable technologies to meet the industry’s net-zero ambitions, as well as achieve the Science Based Targets initiative (SBTi) for net-zero value chain emissions by 2040, we believe that strong collaboration with customers and partners is crucial. We cannot deliver the changes that need to happen alone – that’s why we are working closely with our customers, supply chain partners, governments, societies and other stakeholders.”

Built for heavy-duty applications

A popular choice in a wide range of machinery from excavators and underground mining trucks to crushers and screeners, Volvo Penta’s industrial combustion engines have been proven and optimised to meet customer needs in terms of productivity, uptime and total cost of ownership (TCO). Passive regeneration of the aftertreatment system eliminates unplanned stops during operation, while fuel consumption has been reduced by up to 5% over the previous models.

Further supporting customers who are looking to transition to low-carbon solutions, is Volvo Penta’s dual-fuel hydrogen engine – an evolution of the company’s proven D8 model. The engine mainly uses hydrogen as a renewable fuel source and reduces CO2 emissions by up to 80% without impacting power or performance.

Another aspect of their transformation journey is its growing foothold in electromobility as a system supplier. Volvo Penta’s electric power solutions are backed by connectivity to help customers actively monitor the health of their drivelines in a predictive way throughout their lifespan.