GE has developed a power plant with the flexibility and efficiency to enable greater use of wind, solar and natural gas on the power grid

GE, whose technology helps to deliver a quarter of the world’s electricity, has engineered a first-of-its-kind power plant to deliver an unprecedented combination of flexibility and efficiency. By rapidly ramping up and down in response to fluctuations in wind and solar power, the technology will enable the integration of more renewable resources into the power grid.

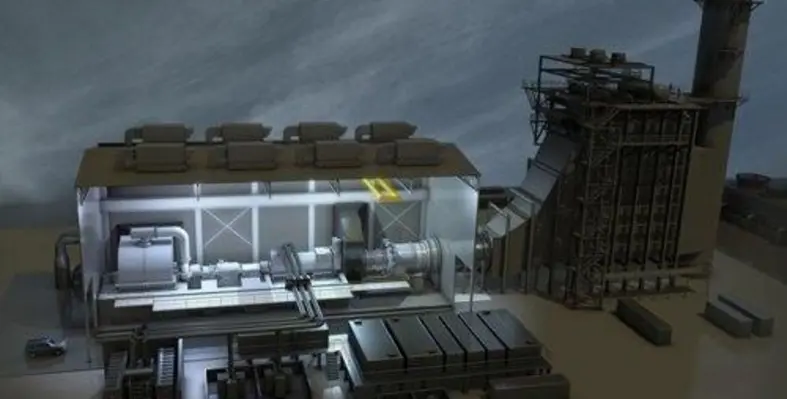

In a combined cycle power plant, greater fuel efficiency is achieved because waste heat is recovered from the exhaust of the gas turbine, converted to steam and then fed to a steam turbine to provide additional energy output. The FlexEfficiency 50 Combined Cycle Power Plant is rated at 510 megawatts and offers fuel efficiency greater than 61 per cent. The plant is the result of an investment of more than $500mn in research and development by GE and a key part of its ongoing work to create and manufacture technologies around the globe that deliver cleaner, more efficient energy.

Flexibility and efficiency

While power plants today can provide flexibility or high efficiency, this power plant will deliver an unprecedented combination of both. GE calls this combination of flexibility and efficiency ‘FlexEfficiency,’ which is essential if renewable power is going to cost-effectively integrate into power grids around the world on a large scale.

GE drew from the company’s jet engine expertise to engineer a plant that will ramp up at a rate of more than 50 megawatts per minute, twice the rate of today’s industry benchmarks. Operational flexibility at these levels will enable utilities to deliver power quickly when it is needed and to ramp down when it is not, balancing the grid cost-effectively and helping to deploy additional renewable power resources like wind and solar. A typical FlexEfficiency 50 plant will deliver enough energy to power more than 600,000 EU homes.

Increasing renewables with natural gas

“As our customers seek to increase their use of renewable energy, the challenge of grid stability sharpens. They are under added pressure to achieve higher levels of efficiency and lower emissions for natural gas power plants. The FlexEfficiency 50 plant creates an immense growth opportunity in a new segment for our gas turbine technology and is in lock-step with our commitment to build a cleaner energy future,” said Paul Browning, president and CEO - thermal products for GE Power & Water. “For years we have been working to develop technology that can, in the same breath, deliver breakthrough efficiency and deal head-on with the challenge of grid variability caused by wind and solar. The need for combined flexibility and efficiency is even more pressing today as countries around the world establish new emissions standards.”

The FlexEfficiency 50 plant is the first product in GE’s new FlexEfficiency portfolio and part of GE’s ecomagination commitment to drive clean energy technology through innovation and R&D investment. The launch follows GE’s recent announcements of the world’s most efficient wind turbine, the highest reported efficiency for thin film solar and $11bn in acquisitions that strengthen a portfolio supporting natural gas and power transmission.

“Much of today’s power generation technology is serving yesterday’s power grid. Institutions and individuals everywhere are looking for cost-effective ways to use solar, wind and gas energy on a large scale. But they often assume that renewable energy can simply plug-in to the existing power grid,” said Steve Bolze, president and CEO of GE Power & Water. “Throughout GE, we have invested to strengthen our global portfolio with a view to delivering efficient power generation across clean energy technologies. We expect this FlexEfficiency breakthrough to help take advantage of abundant natural gas while we simultaneously carve a fresh path to accelerate wider adoption of renewable energy, all with less impact on natural resources.”

Sustainability by design

GE engineers were able to avoid the typical tradeoffs between flexibility and efficiency by approaching the plant design from a total equipment and control systems perspective. The FlexEfficiency 50 plant is engineered for flexible operation by integrating a next-generation 9FB Gas Turbine that operates at 50 Hz, which is the power frequency that is most used in countries around the world; a 109D-14 Steam Turbine, which runs on the waste heat produced by the gas turbine; GE’s advanced W28 Generator; a Mark VIe integrated control system that links all of the technologies; and a heat recovery steam generator.

“With global energy demand expected to double by 2030 and electricity generation accounting for 40 per cent of greenhouse gas emissions, utilities and government bodies are taking a hard look at how to produce power more efficiently,” said Ricardo Cordoba, president of GE Energy for Western Europe and North Africa.

The International Energy Agency maintains that large shares of variable renewable energy are feasible as long as power systems and markets are properly configured so they can get the best use of their flexible resources. The FlexEfficiency 50 Combined Cycle Power Plant offers unprecedented levels of flexibility that will simplify this challenge without sacrificing fuel efficiency.

IMAGES: GE, FlexEfficiency

CAPTION: FlexEfficiency 50 Combined Cycle Power Plant