Optima Life Science, a specialist in the field of web processing technologies, has received additional funding for a test converter specifically designed for the development and testing of innovative manufacturing processes for fuel cells which the company is currently developing

The company already offers production systems for fuel cells with a high output. Building on this experience, the company is currently developing a modular test converter. Innovative ideas and process optimisations, as well as product developments can thus be implemented quickly and easily. In the future, production processes for fuel cells will first be verified in a development environment and then transferred to high performance systems

According to Optima Life Science, further developments in fuel cell technology will foreseeably always require new structures and dimensions of the fuel cells and thus also of the membrane electrode assembly (MEA). The need for development and refinement of manufacturing processes is in high demand. The OPTIMA MTC (Modular Test Converter) is designed for this purpose. The adaptable arrangement of the different processes, the reconfiguration and the addition and removal of process steps become reality. Individual processes and complex process sequences, up to the finished MEA for the fuel cell can be tested.

Another benefit is the reduced economic risk when product development and manufacturing process development can go hand-in-hand. Ideas for process and product optimisation can also be implemented quickly and validated in the course of product development. The knowledge gained can quickly be implemented into production. Last but not least, sampling and small series production can take place on the OPTIMA MTC system.

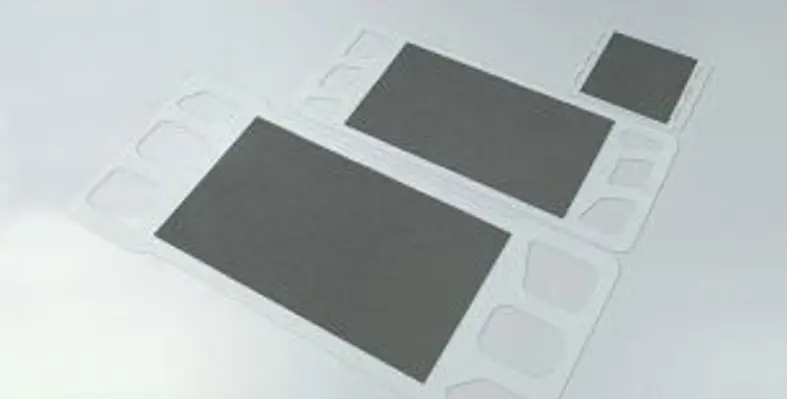

The heart of the fuel cell is the membrane electrode assembly. Hydrogen and oxygen are present and electrical energy and water are produced in an electrochemical reaction. The individual components such as membranes, frame material and gas diffusion layers are each fed from the roll in Optima systems. Individual parts are cut to size and assembled into the MEA in the complex, continuous web process. In order for the fuel cells to achieve the desired level of efficiency, all process steps require maximum precision. In addition to the manufacturing technologies required for MEA production, Optima offers the traceability of each individual MEA with its digital solutions.

Experiences from projects that have already been implemented and inquiries from the hydrogen industry showed that there is an enormous need for product and process development. Optima Life Science responds to this request by developing and building the OPTIMA MTC test converter.

To exploit the full potential of production methods and to support the rapid growth of this future technology, Optima has received funding from the state of Baden-Wuerttemberg. The state government is providing budgetary funds for the development of this technology.