In times of dwindling natural resources and increasingly expensive raw materials, it is a task of central importance in road construction to develop road milling machine designs that are viable for the future and effectively reconcile economical and environmental considerations.

The innovative dual-engine concept implemented in the new W 210 large milling machine realizes a highly economical overall energy balance together with a favourable environmental balance. Benefits in field operation include significant savings in diesel consumption and positive effects on the milling machine’s noise emissions. This is achieved, amongst other things, by application-optimized engine speed ranges and governing of the engine speed in accordance with the travel speed when in transport mode.

Use engine power in line with requirements

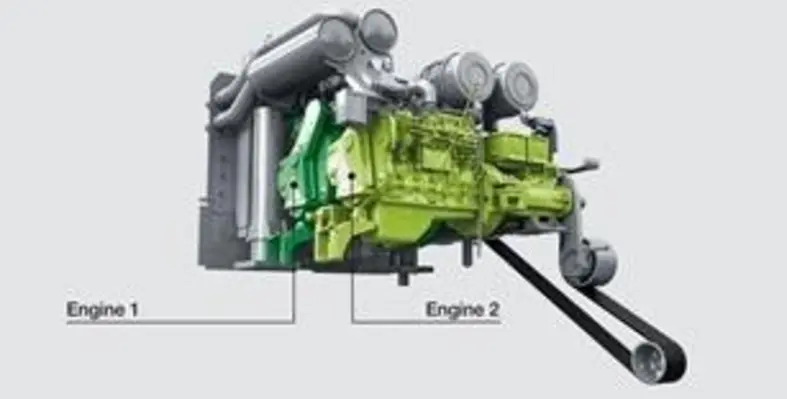

The dual-engine concept is based on the following rationale: engines are exposed to greatly varying performance requirements in different construction projects, which depend both on the material to be milled and on the specified milling depth and milling width. Diesel fuel consumption rates are largely determined by the engine load during the milling process. Building the W 210 with two diesel engines efficiently splits the machine’s drive power: the first engine has an output of 276 kW / 370 HP, and the second engine has an output of 224 kW / 300 HP. This enables one engine only to run in case of lower requirements, such as transport mode or idling times. The second engine is added on for increased performance requirements, and synchronization of both engines is effected in a digital process. Operating both diesel engines in the eco speed range – i.e. at 1,600 1/min – when in milling mode additionally results in tremendous diesel fuel savings even when running at full load. In the annual mean, the new drive concept results in an average reduction of fuel consumption rates of over 25 per cent per cu m of asphalt material milled.

Machine operator decides on the engine power to be used

The machine operator not only independently controls and operates all major functions of the cold milling machine, such as selecting the milling gear, but is also the one who decides when to use the second engine during the milling process.

In field operation, selecting and de-selecting the second engine is effected as follows: when driving the W 210 from the low-loader to the milling site at the start of a milling project, the machine operator pre-selects one engine at the key switch of the cold milling machine, presses the starter button and drives to the area to be milled in transport mode with only one engine running at a fuel-saving, reduced engine speed. The key switch of the W 210 can be set to two different positions: by setting it to position 1, the machine operator selects single-engine operation. By turning the key switch further to position 2, the machine operator pre-selects dual-engine operation. The second engine is started up as soon as he initiates the actual milling process by activating the milling mode via joystick or Level Pro. Should the machine operator then find that one engine is sufficient for the requirements posed by the construction site, he simply turns the key switch back to position 1. After a cool-down phase, the second engine shuts down automatically, and milling continues in single-engine mode.

The dual-engine concept additionally offers an intelligent automatic feature: when the machine operator is working in dual-engine mode, and a break in operation occurs due to waiting times caused by a change of trucks, or because the cold milling machine needs refilling with water or needs to be repositioned on the construction site, the second engine of the W 210 shuts down automatically. The milling machine continues with a single engine, using less fuel as a result. The second engine is started again automatically as soon as the milling operation is resumed.

Saving costs the right way

A broad range of milling applications permits the W 210 to be driven in single-engine mode only in order to draw only that amount of power that is needed for the job at hand. Single-engine operation is entirely sufficient for simple loading operations, such as the milling of gravel layers. Economical operation with a single engine is also fully adequate for milling off any remaining strips of the passes to be milled at the end of the construction project. The removal of soft or highly brittle surface courses, especially at very low milling depths of less than three centimetres, is yet another application ideally suited to operating the machine in single-engine mode.