Perkins showcased a comprehensive range of off-highway power system technologies at bauma, from fuel flexible optimised internal combustion engines to hybrid systems and fully electrified offerings

All are designed to support customers with their diverse needs in different markets as they navigate a complex and evolving energy landscape, which calls for flexible solutions and an agile response.

Models on show included the all-new 2600 Series, an adaptable power-dense industrial engine delivering up to 515 kW (690 hp) in power. Compatible with HVO and biodiesel blends, the 2600 Series provides flexibility whilst delivering power, reliability and performance. Also on display was the new 906J-E36TA, 106kw variant of the 3.6 litre engine, which offers increased power versus the current 3.6 litre for applications that need more power in a compact package, and can run on a range of fuels.

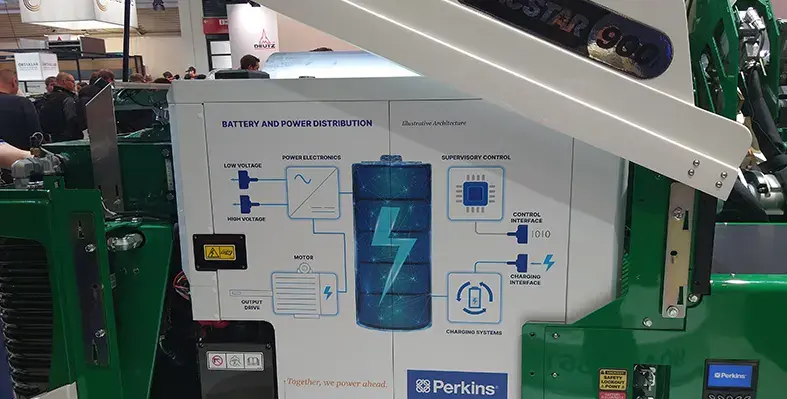

A highlight was the new battery electric power unit technical demonstrator, which Perkins debuted at the show, designed to enable off-highway OEMs to seamlessly transition from diesel to a battery electric powertrain.

The fully integrated plug and play battery electric power unit can be ‘dropped in’ to a machine to replace a diesel engine. The system consists of a Perkins battery along with inverters, motors and on-board chargers – all packaged up into a compact drop-in system to support seamless transition from diesel to electric.

The Perkins battery electric power unit has been put to the test in a McElroy TracStar® 900i pipe fusion machine as a commercial demonstrator, with the battery electric power unit replacing a 3.6 litre 904 Series industrial open power unit. The power unit’s compact design enabled the seamless transition from diesel engine to electric, with the power unit fitting within the same chassis space and having the same mechanical connection and electrical interface points as the 3.6 litre diesel engine power unit it replaced. The work was all carried out at Perkins’ premises in Peterborough, UK.

“The customer wanted to have a zero emissions solution, so we’ve worked with them to design a full powered solution that can replace the engine with a battery electric power unit. It basically takes away the complexity and engineering challenges of integrating a battery,” explained Danielle Aiken, EAME marketing manager at Perkins.

“For many of our customers, moving to battery is a big challenge, involving a lot of engineering time and technical resource. We worked with McElroy to understand what they needed to achieve from a power standpoint, and then integrated that into the battery system. This demonstrator illustrates the journey that we have been through, and the collaboration between the OEM and Perkins to take away that complexity.”

Given the flexibility of the system, Perkins is now looking to work with different OEMs on different applications, whether it be a wheel loader, an excavator or a range of different systems. A selection of applications powered by a range of solutions were demonstrated on a video at the Perkins stand.

Discussing the Middle East and Africa markets, Aiken commented that while they are less regulated in terms of emissions, factors such as fuel consumption and energy efficiency are a concern, so the possibility of taking a traditional diesel engine and making it more power dense could be an attractive proposition.

“The new 2600 Series on show at bauma, which goes into production in 2026, is also available for less regulated territories like the Middle East and Africa,” added Annette Ward, marketing communications manager.

“To meet customer needs, the 13 litre platform is designed to achieve best-in-class power density, torque and fuel efficiency, with longer service intervals supporting the productivity of heavy duty off-highway equipment.”