KPS, a global innovator in high density polyethylene (HDPE) piping, has delivered the world’s first 6” double wall conductive HDPE piping system

The new system has been designed to combine KPS piping’s safety and installer-friendly qualities with a high flow rate of up to 2,500 litres per minute to meet demand from applications including depots, fuel distribution, ports, mining, rail, data centres and many more.

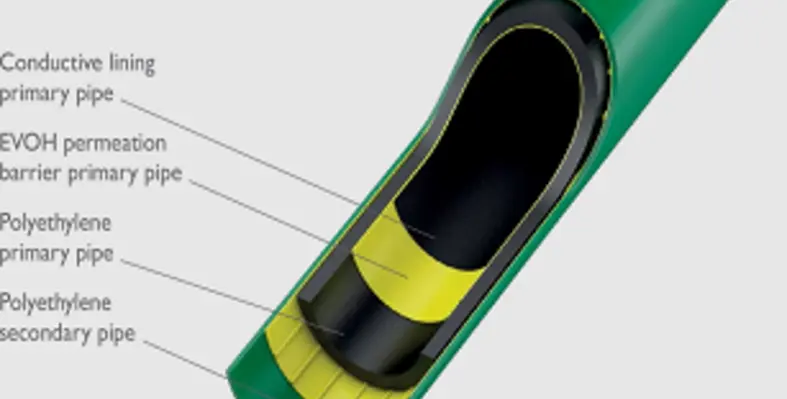

A conductive inner layer allows static electricity to safely dissipate into the earth, while a secondary pipe provides an extra layer of protection and enables interstitial monitoring.

Staffan Helleday, technical director at KPS, commented, “When fuel flows through a pipe, it creates friction which creates an electrical charge on the pipe wall. If the material is not conductive, the charges (free electrons) can’t flow anywhere and consequently accumulate until a rapid discharge can occur: a spark.

“In 1997 we developed the world’s first conductive HDPE piping to combine the lightweight, corrosion-free benefits of HDPE with the conductive safety of metal. A conductive inner layer allows static electricity to dissipate into the earth.

“Now, a number of countries, including China, Germany, Slovenia, Croatia and the Baltic States, require conductive piping to be used for filling stations, as well as a number of major oil companies, including BP, OMV, PetroChina, Q8, Aral, Total and Esso. As future fuels containing oxygen which generate more friction are increasingly used, conductive piping becomes ever more important.”

KPS’ new 6" double wall conductive piping system consists of a 160 mm primary pipe and a 200 mm secondary pipe, providing an extra layer of protection and enabling interstitial monitoring. Suitable for sensitive liquids like fuel and chemicals, including petrol, diesel, biodiesel, ethanol blends, AdBlue, Jet-A1, alcohols, acids and other chemical products.

Like all KPS piping, the new 6” system is engineered for installers to reduce cost and build time. The complete range of fitting and components for the new 6" conductive double wall pipe system are electrofusion welded, with no butt welds needed, and the range is supported by the KPS technical team, including training and certification (classroom and on-site).