New turbine generator is an important component in the fight against climate change

In the European Union, there are efforts under way to reduce emissions of the climate killer CO2 for 2020 by 30 per cent, and to make this a binding target. Research and industry are called upon to draw up and implement innovative climate protection projects which will work worldwide.

An ambitious energy recovery research project, which is funded by the German Federal Ministry of Economics and Technology under a resolution by the Deutsche Bundestag (Germany’s parliament), is soon to start production at DEPRAG SCHULZ GMBH & CO. Managing Director Dr. Eng. Rolf Pfeiffer explains the underlying concept.

“In many industrial processes, process gas escapes unused into the atmosphere. Our basic idea was to tap these gases for the further generation of energy.”

Energy recovery from process gases, however, is not a new concept. Rolf Pfeiffer: “What is new with our development is that it enables the conversion of even small amounts of residual energy in the range of 5 to 20 kilowatts into electricity using a small, compact and decentralised energy recovery unit.”

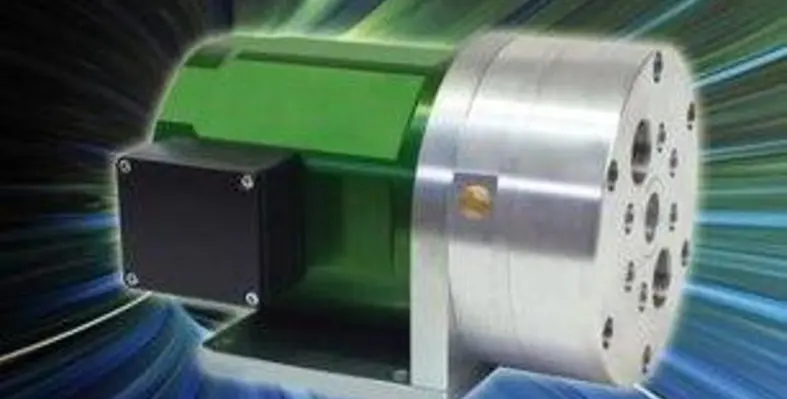

As a result of the extensive research, the first prototypes of the innovative DEPRAG turbine generator are now finished in the development lab. The patent has been registered; test series with the prototypes have been successfully concluded. Dr. Eng. Rolf Pfeiffer says:

“We can now go into production with our product and are looking for partners who want to use this innovative system for energy recovery in their facilities. Our recovery system can be used in a variety of applications to convert process gases into electricity or even to utilise unused surplus heat.”

Usability

Energy recovery with the DEPRAG turbine generator can be applied in many areas of industry. In the smelting of metals, for example, the melting tanks are cooled by compressed air. The compressed air flows through cooling channels and absorbs heat. Normally, it is then released into the atmosphere without being used. With the new turbine generator, what is actually a waste product can be reused profitably. The energy absorbed from the heat can be converted to electricity by the microexpansion turbine and the integrated generator and fed into the power grid.

To date in large biogas plants and cogeneration units, residual energy has been converted to electricity based on the ORC (organic Rankine cycle) process, however the power range of these installations is between 200 and 1,500 kW. But today, it is smaller biogas plants and cogeneration units that are increasingly being built. The electrical efficiency of such plants can be effectively optimised with the new turbine generator by also allowing smaller amounts of waste heat to be used efficiently in an ORC recovery process. Thus, the overall efficiency of these plants can potentially be increased to more than 45 per cent. In accordance with the German Renewable Energy Act (EEG), a technology bonus of 2 cents/kWh will be earned for the whole plant.

Summary

Managing Director Dr. Eng. Rolf Pfeiffer sees great market potential for the DEPRAG turbine generator. He summarises the advantages: “Even smaller amounts of residual energy can be converted to electricity at a reasonable price with the compact recovery system.” The ecological benefits of this sort of energy recovery also pay off financially. The feed-in tariff in accordance with the Renewable Energy Act (EEG) offers an additional incentive. The investment costs should also remain affordable. Dr. Eng. Rolf Pfeiffer says: “It is certainly imaginable that in the future we will be able to offer the turbine generator unit for 10 kW for less than 10,000 euros ($15,000) at a corresponding volume.”