Atlas Copco’s new High Precision Tunnelling (HPT) concept points the way to further process refinement and greater cost efficiency.

HPT features five innovative options for drill rigs and machines, based on the latest technology and tunnelling know-how. The efficiency of Atlas Copco’s advanced tunnelling equipment is globally recognised. Learn more about the five part concept and enjoy a still higher level of tunnelling precision – and optimal productivity.

Professional planning tool

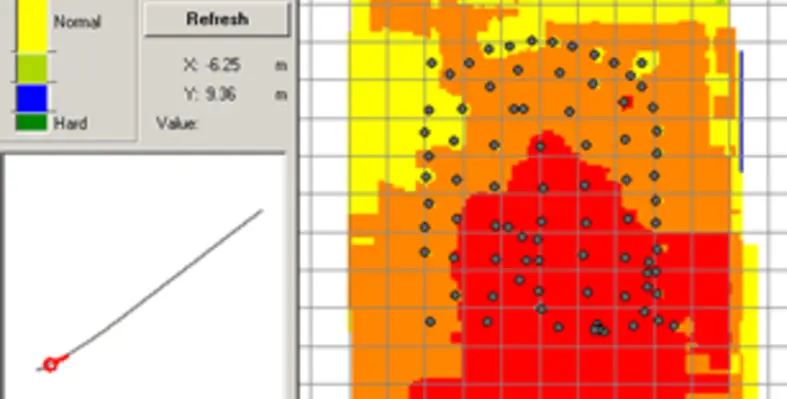

Tunnel Manager is the intelligent PC-software that enables the worksite office to provide operational support to Atlas Copco Boomer rigs equipped with the Rig Control System (RCS). Tunnel Manager is used to plan, store and evaluate data for the drilling process. Transfer of data to the drill rig ensures more efficient and precise navigation, generating significant cost efficiencies. Tunnel Manager comprises the latest advances in computer technology and is available in three versions – Tunnel Manager, Tunnel Manager Pro and Tunnel Manager MWD – involving progressive gains in functionality. The most advanced version permits analysis of accumulated data, using Atlas Copco’s upgraded Measurement While Drilling (MWD) technique. This allows rapid translation of raw data into specific properties such as rock hardness, crack zones and more, which can be used to correct and fine-tune the tunnelling process.

Minimum timeloss and more drilling hours

Good communication with the underground drill rig is one of the keys to efficient tunnelling. Atlas Copco’s Rig Remote Access (RRA) option ensures rapid and secure transfer of the latest data to and from the drill rig – as well as secure storage of all necessary information. With the drill rig online, the whole organisation has constant access to the latest information. The production planning department can initiate immediate analyses of incoming data, automatic updates eliminate the need to manually collect new drill plans for the rig operator, and service personnel can conduct online diagnoses and order appropriate replacement parts prior to actual service calls. The result?

Minimum timeloss and a lot more drilling hours. With the Rig Remote Access Server software, online file transfer is assured, even when the drill rigs are temporarily beyond WLAN range.

Efficient precision

Efficient precision

Time is money. Precision is also money. With Total Station Navigation (TSN), the rig can rapidly be navigated into precisely the right position – every time, and with limited need of surveyors. Navigation is not only extremely precise (accuracy better than 1cm compared to the more normal 10cm), it is fast: no more than five minutes, compared to the 10–30 minutes for manual methods. Given a tunnel 2,000 metres long, this translates into savings of about EUR 100,000. And more precise navigation also cuts costs, due to reduced over- and underbreak. Navigation is simply conducted by the rig operator, using a tripod-mounted Total Station, in combination with prisms mounted on the rig and tunnel walls. With additional data on fix points and tunnel line from Tunnel Manager, the navigation process is complete.

Save time and money

In tunnelling, the right profile from start saves a considerable amount of time and money. The Atlas Copco Tunnel Profiler is an intelligent 3D-scanning system for rapid and high-precision tunnel profiling. A section can be scanned immediately prior to drilling the next round, requiring very little extra time. Data is processed by the Atlas Copco Tunnel Profiler software and the rig operator is informed about any over or underbreak in a matter of minutes. This means drill plans can be corrected very quickly. In short, the Atlas Copco Tunnel Profiler reduces costly finishing to an absolute minimum. Rapid adjustment of drill plans can save up to 5cm in overbreak. In a tunnel with a 40m² profile, this can yield savings in overbreak-costs of about EUR 125,000 per kilometre, in terms of concrete and man-hours.

Rapid acquisition of vital drilling data

By applying new technology, we acquire an increasingly detailed understanding of the rock mass, for more efficient tunnelling and drift mining. The Measurement While Drilling (MWD) technique has enjoyed rapid development, through computerisation of the drill rigs. Atlas Copco’s upgraded MWD is a rig option offering rapid acquisition of vital drilling data, such as penetration rate, feed force, rotation speed and more. With Tunnel Manager MWD, the data can also be used to analyse rock hardness, crack zones and other relevant rock mass characteristics. Thorough knowledge of the rock’s properties means the tunnelling process can be adjusted during drilling operations, for improved safety, efficiency and economy.

Always a correct bolt pattern

Bolt Angle Indication is support software that gives guidance of the rock bolting operation in mining and tunnelling projects. The Bolt Angle Indication system focuses on guiding the operator to install bolts with the correct distance between the bolts. By using this guidance system, there is no longer any need to mark the walls to achieve the correct bolt pattern, and if different operators install bolts, the job will always be done with the same spacing and with minimum human error.

Safe rock support system

Bolt Plan Navigation is a support software that enables planning, guidance and logging of the rock bolting operation in mining and tunnelling projects. To use a correct bolt pattern adapted for existing rock conditions, is essential to obtain a safe rock support system. Today, different methods of installing the correct bolt pattern are used, but the one thing they all have in common is that they rely on the operator’s ability to manoeuvre the bolting equipment. Bolt Plan Navigation system enables planning of the rock support in underground mining and tunnelling operations. With the Total Station Navigation function, which is included, the rig can rapidly be navigated into precisely the right position - every time, and with limited need of surveyors. With Bolt Plan Navigation it is easy to see where bolts are to be installed without guide marks painted on walls and roofs. You will receive reports about bolt types, amount of cement used and other data that can be saved for future analysis. The logging function shows how many bolts have been installed and their exact position.