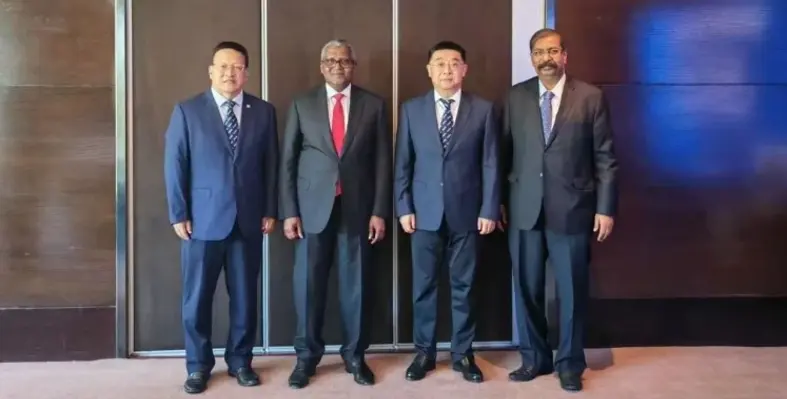

The collaboration combines XCMG's expertise in innovative, eco-efficient technologies with Dangote Group's extensive operational footprint. (Image source: XCMG Machinery)

XCMG Machinery, a global leader in green construction machinery and mining equipment, has announced a landmark strategic alliance with Dangote Group, Africa's largest and most diversified industrial conglomerate

The collaboration combines XCMG's expertise in innovative, eco-efficient technologies with Dangote Group's extensive operational footprint, setting a new standard for environmental responsibility across Africa's industrial and infrastructure sectors.

Key areas of focus include:

-

Greening operations across Africa: XCMG will provide electric and hybrid eco-efficient construction and mining equipment, along with advanced fleet management systems, to enhance sustainability across Dangote Group's operations.

-

Collaborative innovation for sustainability: The companies will jointly develop tailored solutions for cement, fertiliser, agriculture, and mining sectors, emphasising energy efficiency, emissions reduction, and circular economy principles.

-

Knowledge sharing & technical R&D: Joint research and technical cooperation will foster next-generation green technologies adapted to Africa’s needs.

-

Clean energy development: Both partners will explore investments in solar power, charging stations, and other clean energy infrastructure to support Dangote Group’s sustainability objectives and Africa’s energy transition.

"We are honored to be selected as a strategic partner by the esteemed Dangote Group. This collaboration is a strong endorsement of our 'Green and Intelligent Manufacturing' strategy," commented Dongsheng Yang, chairman of XCMG Group and XCMG Machinery. "By combining our advanced technological capabilities with Dangote's unmatched presence and vision across Africa, we are confident in our ability to significantly contribute to the continent's sustainable industrial development."

"This strategic alliance with XCMG is a cornerstone of our long-term vision for sustainability and operational excellence. By integrating advanced green technologies into our core operations, we are not only reducing our environmental footprint but also setting a precedent for responsible industrial leadership in Africa," remarked Aliko Dangote, President and CEO of the Dangote Group.

The partnership between XCMG and Dangote Group is set to deliver transformative impact, accelerating the adoption of green technologies and establishing a new benchmark for corporate leadership in the global fight against climate change.